The year 2021 saw the automotive industry suffer from a debilitating chip shortage whose effects are likely to be felt later in 2022. A scarcity of semiconductors, the small but vital chips that calibrate fuel injection, drive infotainment systems, and supply the brains for cruise control, has thrown the auto industry into disarray.

The timing of the shortage could not have come at a worse time, with the automakers still reeling from the effects of the Coronavirus pandemic. While the shortage has affected many industries, the automotive industry has borne the brunt of the situation.

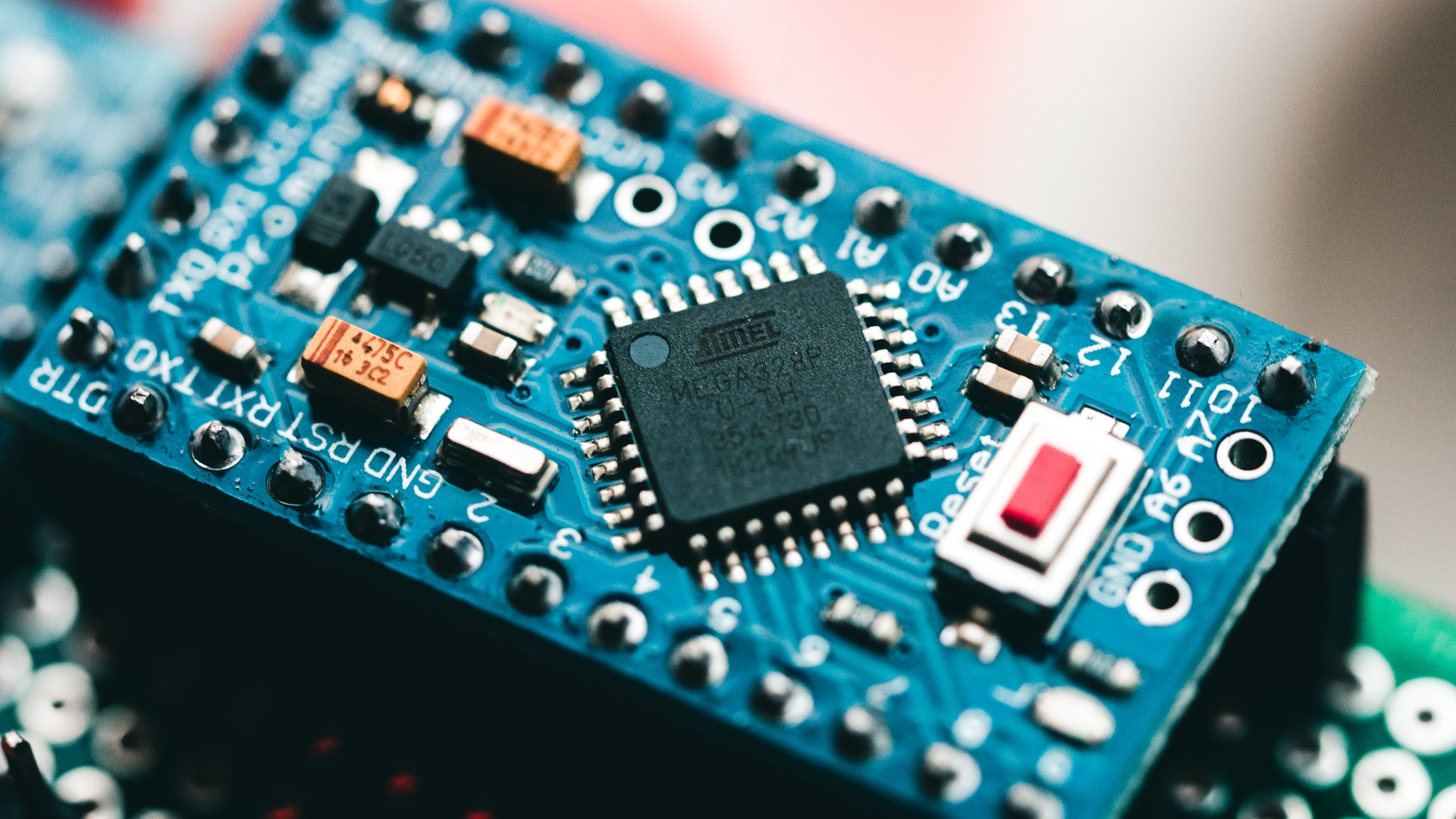

But why has the vehicle industry borne the brunt of the global chip shortage? The simple explanation is that modern cars have grown dependent on microchips to perform various functions, such as detecting tire pressure issues and triggering safety features.

A typical vehicle requiring over 1400 microchips has left the industry in dire straits. The impact has been devastating, with some automakers forced to close down manufacturing operations.

Companies like General Motors saw their sales plummet by 30 percent in 2021. On its part, Ford’s net revenues dropped by 24 percent in the third quarter of the year. According to some estimates, the chip supply chain issues cost the auto industry upwards of $210 billion in revenue.

What Led to Chip Shortage in the First Place?

During the pandemic, consumers began buying all sorts of sophisticated products that had one thing in common: they were all equipped with one or more microchips. Stuck at home and instantly in need of suitable devices for collaborating, learning, and entertaining themselves online. Laptops, gaming PCs, tablets, monitors, smart TVs, appliances, security systems, and video gaming consoles—demand for these and other chip-dependent gadgets climbed to unprecedented heights during the pandemic.

In 2020, tablet sales increased by roughly 14% over 2019, and personal computer sales increased by 11% over 2019, the largest rise since 2010. Over the same duration, revenue from game consoles shot to $11.9 billion or 8%, and annual sales of smart TVs increased by 7%. Because of the unexpected spike in demand for smart, chip-enabled devices, the industry required massive quantities of all various kinds of chips simultaneously.

Like so many other facets of the Covid-19 economy, this caught semiconductor supply chain players off guard. Since they were caught unawares, they couldn’t make enough of the correct chips quickly enough to meet demand. To worsen an already bad situation, chipmakers opted to supply the chips to the higher-paying electronics industry.

How has the Chip Shortage Impacted Car Buyers?

Drive by any virtually empty showroom floor to get a sense of how this works on the ground. Purchasing a new or used automobile has become more complicated. Before the crisis, car manufacturers had 70 to 80 days’ supply of several models on hand, allowing buyers to strike a deal and drive away in their new vehicle. Inventories in the United States have dropped to levels not seen since the global financial crisis, with inventories as low as ten days’ worth.

There were few options for new automobile buyers or those returning a lease. Customers found themselves ordering a new vehicle and waiting months for it to arrive. They were also taken aback by the price tag. According to J.D. Power, the average transaction price for a vehicle has surpassed $45,000, and the average incentive has dropped to around $1,600.

With fewer trade-ins, fewer used cars were available, resulting in even higher price hikes. As shown in a white paper released by KPMG, new automobile prices increased by roughly 12% throughout the year, while used car prices increased by more than 42%.

Some purchasers may be fortunate enough to get a new car, but it may lack features that require specific chips. For instance, Porsche has informed U.S. dealers of its inability to deliver the luxurious seats in its Macan SUV and informed car buyers in the United States that they may have to wait an extra 12 weeks for their Porsche’s due to lack of a microprocessor that monitors tire pressure.

The Nissan Ariya, Rivian R1T and R1S, and the Tesla Cybertruck were among other anticipated new car introductions that were postponed. Many automakers, notably GM, prioritized electric vehicles.

The good news is that new vehicle inventories are improving. For the first time since July 2021, the United States had a monthly supply of more than 1 million vehicles for sale in December.

Vehicle Protection Plan With CarGuard

To most people, a car is among their most prized possessions. This means protecting it from avoidable damage is essential.

However, even with the most meticulous care, cars still face challenges such as accidents, worn-out parts, and warranty coverage issues. And with the ongoing chip shortage, you may be stuck with your current car for longer than you had anticipated. Keep your vehicle in shape with a CarGuard vehicle service plan.

CarGuard takes a unique approach to their relationship with clients and customers. This relationship is critical to CarGuard. Their mission is to quickly adjudicate your claims and provide their customers with world-class service. Here are their protection plans:

- CarGuard Platinum Protection Plan

- CarGuard Gold Protection

- CarGuard Powertrain Protection

- Prepaid Maintenance Plan

- CarGuard Flat Rate

CarGuard Vehicle protection plan has a $12,500 limit of liability. On top of that, all protection plans include a bonus roadside assistance and a rental car program. Get in touch with them, and they’ll help you choose the best plan for your vehicle protection.