Plastic injection molding is a widely used manufacturing process for producing plastic parts in large quantities. It involves injecting molten plastic into a mold cavity to create a desired shape. This method of production is preferred because of its speed, efficiency, and accuracy. In this article, we will provide a comprehensive guide to plastic injection molding, including the process, advantages, disadvantages, and applications.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that involves injecting molten plastic into a mold cavity under high pressure. The molten plastic is then cooled and solidified to create a plastic part with a desired shape. The process is widely used for producing plastic parts in large quantities and is commonly used in the production of items such as automotive parts, toys, medical equipment, and electronic components.

The Injection Molding Process

The injection molding process consists of several steps, including:

Mold Design: The first step in the injection molding process is the design of the mold. The mold is designed to create a desired shape and is typically made of metal.

Plastic Pellets: Next, plastic pellets are loaded into the injection molding machine. The pellets are melted and then injected into the mold cavity.

Injection: The molten plastic is injected into the mold cavity under high pressure. The pressure ensures that the plastic fills the entire cavity.

Cooling: Once the plastic has been injected, the mold is cooled. This process solidifies the plastic and allows it to take on the desired shape.

Ejection: Finally, the plastic part is ejected from the mold.

Advantages of Plastic Injection Molding

There are several advantages of plastic injection molding, including:

High Efficiency: Plastic injection molding is a highly efficient manufacturing process. It allows for the production of large quantities of plastic parts in a short amount of time.

Accuracy: Injection molding is an accurate manufacturing process. It allows for the creation of complex shapes with a high degree of accuracy.

Versatility: Injection molding can be used to produce a wide range of plastic parts. It is used in the production of items such as automotive parts, toys, medical equipment, and electronic components.

Low Waste: Injection molding produces very little waste. Any excess plastic can be reused in the manufacturing process.

Disadvantages of Plastic Injection Molding

Despite its many advantages, plastic injection molding also has some disadvantages, including:

High Initial Cost: The initial cost of setting up an injection molding operation can be quite high. This includes the cost of the injection molding machine, the mold, and the necessary infrastructure.

Design Limitations: The design of the plastic part must be carefully considered when using injection molding. Certain shapes may not be possible to create with injection molding.

Applications of Plastic Injection Molding

Plastic injection molding is used in a wide range of applications, including:

Automotive Parts: Injection molding is used to produce a variety of automotive parts, including dashboards, bumpers, and door panels.

Toys: Injection molding is used to produce a wide range of plastic toys, including action figures, dolls, and board games.

Medical Equipment: Injection molding is used to produce medical equipment, including syringes and inhalers.

Electronic Components: Injection molding is used to produce electronic components, including switches, connectors, and housings.

Plastic Injection Molding: A Technical Overview

Plastic injection molding is a highly precise and repeatable manufacturing process that involves injecting molten plastic into a mold cavity. This process is widely used in the production of a variety of plastic parts and components, from small medical devices to large automotive parts.

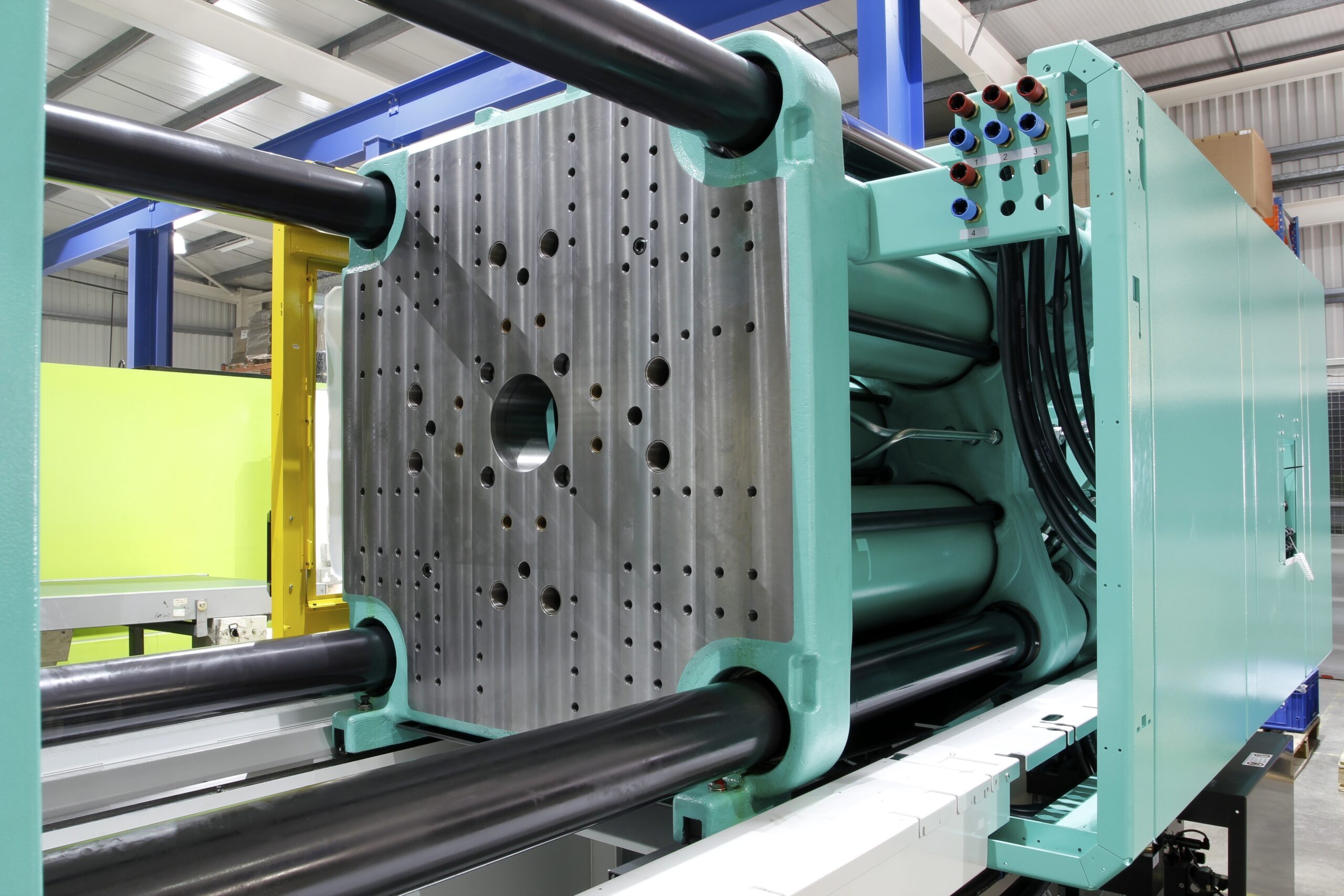

The Injection Molding Machine

The injection molding process begins with the injection molding machine, which consists of a hopper, an injection unit, and a clamping unit. The hopper holds the plastic pellets, which are then fed into the injection unit. The injection unit melts the plastic pellets and injects the molten plastic into the mold cavity under high pressure. The clamping unit holds the mold in place and applies pressure to keep it closed during the injection process.

The Mold

The mold is a key component of the injection molding process. It is typically made of steel and consists of two halves, the cavity and the core. The cavity is the space into which the molten plastic is injected, while the core forms the internal features of the part. The mold is designed to produce the desired shape and can be highly complex, with multiple parts and features.

The Cooling System

After the plastic is injected into the mold cavity, it must be cooled and solidified. The mold is typically equipped with a cooling system, which uses water or oil to extract heat from the molten plastic. The cooling time can vary depending on the part size, wall thickness, and material, but it is an essential part of the process to ensure the final product is of high quality.

The Ejection System

Once the plastic has cooled and solidified, the mold is opened, and the part is ejected from the mold cavity. The ejection system is responsible for removing the part from the mold without damaging it. This can be done using ejector pins, air blasts, or other mechanisms.

Material Selection

The plastic material used in injection molding can vary depending on the application and the desired properties of the final product. Common materials include polypropylene, polyethylene, polystyrene, and acrylonitrile butadiene styrene (ABS). Each material has its own advantages and disadvantages, such as strength, durability, flexibility, and cost.

Quality Control

Quality control is an important part of the injection molding process. It involves monitoring the process parameters, such as temperature, pressure, and cooling time, to ensure that the final product meets the desired specifications. Defects can occur during the injection molding process, such as warping, sink marks, and flash, and it is important to detect and correct these issues as early as possible.

Conclusion

In conclusion, plastic injection molding is a versatile and precise manufacturing process that is widely used in the production of plastic parts and components. It involves the use of an injection mold service to produce high-quality parts that are consistent in size, shape, and performance. With the right equipment, materials, and expertise, injection molding can be a cost-effective and efficient way to produce large volumes of plastic parts for a wide range of applications.