This is a crucial method and procedure in natural gas processing due to the reasons for getting rid of moisture and other unwanted elements. An important material utilized in this process is Zeolite 3A due to the fact it has the ability to adsorb water molecules while passing other components of natural gas regardless of their small size. In a new article, the author appreciates the role of Zeolite 3A in natural gas drying and also stresses on the significance of selecting the right zeolite powder supplier.

Features

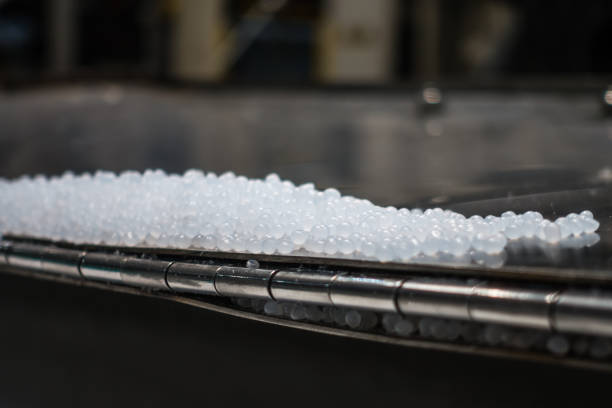

Zeolite 3A is a type of molecular sieve that has the pore diameter of about 3 angstroms and is planned for the adsorption of water molecules only. Due to the porous and three dimensional construction of Zeolite 3A it is the most suitable material in the process of drying of natural gas since it can selectively scoop out moisture. In contrast to other desiccants, Zeolite 3A only absorbs water and does not chemisorb molecules with other gasses within the gas flow. This selectivity is very important while drying natural gas because it keeps the qualities of natural gas intact and removes only moisture without any interference on other components. Zeolite 3A is a chemically unreactive and thermostable material and can therefore be suitable for natural gas separation where the process conditions may be severe. For this very reason, Zeolite 3A sourced from a good manufacturer of the powdered material is very reliable for natural gas dehydration purposes.

Dry Natural Gas

Drying is a vital stage in natural gas processing because water in natural gas leads to several challenges during transportation and utilization. Water in natural gas can create problems with gas hydrates, these are substances similar to ice that may obstruct the pipeline or units. This interferes with the gas flow and may at the same time; cause damages that could be expensive and may lead to safety issues. Equally, condensation of moisture in pipelines lead to corrosion of the pipelines hence costly repair and pipeline downtimes. Through the application of Zeolite 3A for the dehydration of natural gas, these problems may be prevented so as to enable the safe and efficient transportation and utilization of the gas. Also, the naturally dried gas is less emissive and provides better performance to the system which is powered by the natural gas. Zeolite 3A of a high class not only accelerates the process of drying but also increases the stability and safety of the natural gas supply, the sustainability of which is crucial for energy systems.

Use of Zeolite 3A

Zeolite 3A is used in many processes involved in natural gas treatment and purification and in the distribution of this gas to consumers. A major use of Zeolite 3A is the drying of natural gas during its production from subterranean fields and wells. Zeolite 3A is applied to the operation to eliminate the moisture in the gas as it is escalated to the surface, avoiding formation of hydrates and other problems which may affect the extraction process. This is particularly so because water is calamitous in operations such as offshore drilling since it deepens complications and hikes costs. Also, the application includes the stages of preliminary and subsequent treatments of the natural gas where Zeolite 3A assists in the dehydration and the removal of some other undesirable additives before the gas is sent for pipeline transportation. This is important to ensure that the gas being produced meets the high qualities of the market that is fitted into transports and usage. It is also used in storage facilities since it assists in conserving the quality of stored natural gas or methane in their storage via preventing the infiltration of moisture and other impurities. It is thus important for industries such as natural gas processing specific to zeolite 3A, to get the best quality Zeolite 3A from the right supplier of powder zeolite.

Guide

Relative to other processes, the efficiency of the natural gas drying by Zeolite 3A very much depends on the quality of the product, for this reason, a choice of a supplier of the zeolite powder needs to be made. With a supplier you can trust, you will get Zeolite 3A of decent quality that is standard on the market and customized for your needs. To this end, they offer materials that have been through rigorous testing in terms of purity, adsorption rates and product endurance to the environment that is usually experienced in your line of business. A good supplier will also be able to offer consultation services to ensure you get the most out of your natural gas drying. This entails information on how to choose the correct grade of the Zeolite 3A; guidelines on regeneration as well as general care in order to have the longest cycle possible. A competent supplier should advise on the right regeneration techniques to be used to rejuvenate the molecular sieves on the market hence lowering operational expenses. Furthermore, if one has a working relationship with a supplier for the Zeolite 3A, this means that one will be able to have a consistent supply of the same hence reducing the many business interferences that may be caused by insufficient supply. When you use the services of a good supplier in the provision of zeolite powder, you will be in a position to make a lot of improvements in the aspects of your natural gas drying processes thus enhancing returns in productivity and a decrease in expenditures.

Conclusion

The application of the natural gas drying process involves a particular kind of zeolite known as zeolite 3A which has unique characteristics that cannot be matched by any other material in the market in as much as it is very effective in the removal of moisture and thus ensuring the safe and effective transportation and utilization of natural gas. The properties of promise make it an essential commodity in the natural industry to reduce incidents such as pipeline obstruction, rusting, and poor standard of the gas. The capability of the Zeolite 3A to condense water and only that while passing hydrocarbons means that the natural gas will remain highly energetic, a characteristic that is very important in industries as well as to consumers. The proper selection that the industries have to opt for should be a high-quality Zeolite 3A from a reliable zeolite powder manufacturer so that it can provide better output for the natural gas drying , high-quality products, and lesser costs for the industries. Since clean and efficient energy is on the rise, the use of Zeolite 3A for natural gas separation will remain relevant and thus companies that deal in natural gas processing ought to consider working closely with Zeolite 3A suppliers to ensure that they get a very reliable and high performing product.