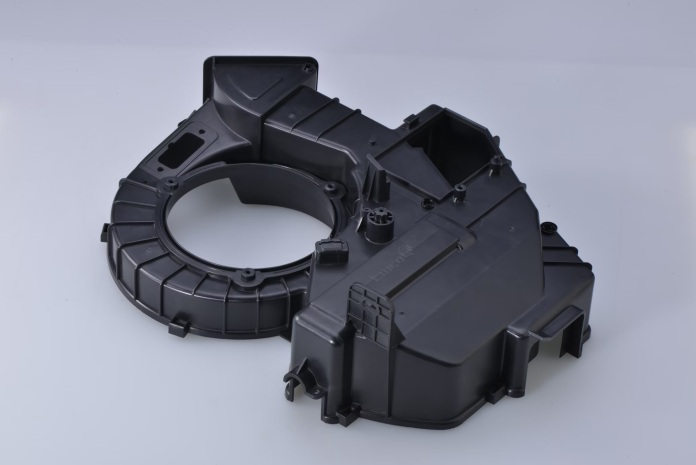

Obstacle is a part of daily routine in the world of custom plastic injection molding. This complex procedure requires not only a thorough knowledge of materials and equipment but also the capacity to solve many problems that may occur during production. The purpose of this guide is to provide information on the most common challenges in this field and their solutions, in order to make the transition from the custom injection mold to the final product as seamless as possible.

Material Behavior

The success of custom plastic injection molding is largely determined by the choice of materials. Various polymers have different responses to the stress of injection molding processes. For example, warping or shrinkage may happen with the materials that are not suitable for the particular design of a custom injection mold. The knowledge of material properties such as melting temperature, flow rate, and cooling time is critical for mold makers to anticipate and prevent these problems.

Precision in Mold Design

The mold design and manufacturing accuracy are the main factors that influence the quality of the final product. Inaccuracies in the mold cause the part to have defects like improper fit, surface imperfections, or structural weaknesses. With the help of advanced CAD software and CNC machining, mold makers are able to attain the level of precision needed for the effective custom plastic injection molding.

Injection Molding Parameters

The parameters of the injection molding machine, including temperature, pressure, and injection speed, must be adjusted precisely to the material and the mold design. Improper settings can cause a range of problems, starting with incomplete filling of the mold and ending with excessive internal stresses in the final part. These parameters need to be monitored and adjusted on a regular basis for the sake of high-quality production.

Ensuring Adequate Cooling

Cooling is crucial for avoiding deformations and guaranteeing the dimensional accuracy of the injected parts. In the same way, a properly developed ejection system is vital to remove the part from the mold without any harm. To avoid these obstacles, mold manufacturers should carefully design cooling and ejection systems suitable for the particular custom injection mold and the part being produced.

Training and Expertise

The skill of the people running the injection molding machines is not to be underestimated. Technology, no matter how advanced, still requires human supervision to detect and solve problems as they occur. Continuous investment in training and development of operators is a must for mold manufacturers to have their teams capable of dealing with the intricacies of custom plastic injection molding.

Conclusion

Custom plastic injection molding is a discipline that requires accuracy, knowledge, and a continuous dedication to quality. Recognizing the critical contribution of human expertise in troubleshooting and problem-solving makes it possible to produce perfect custom injection mold parts. By faithfully applying these principles, mold manufacturers can remain at the forefront of the demanding yet satisfying field of custom plastic injection molding, transforming creative concepts into high-quality reality.